ABOUT US

Diamond Cement Guinea

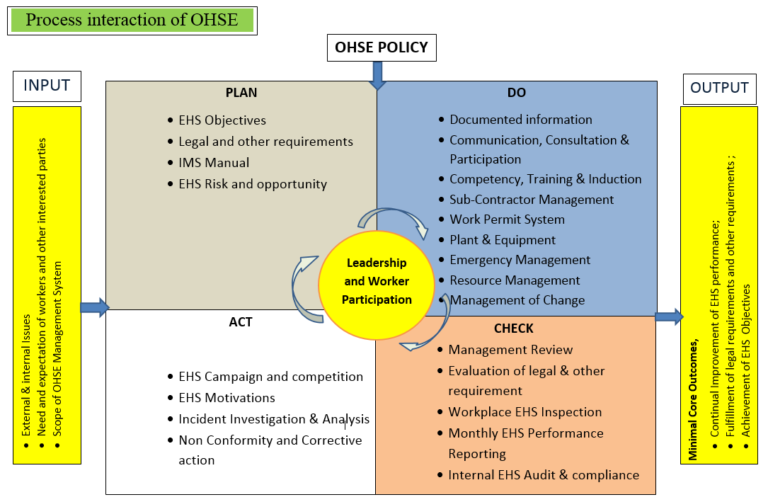

HEALTH SAFETY AND ENVIRONMENT

OBJECTIVES AND GOALS

OBJECTIVES

The OHSMP serves as a reference guide to all the staff, workers, and contractors at DCGN. It includes management systems, the main objectives of which are;

- To promote and ensure an optimum standard of health, safety, and environment including statutory requirements and legislations.

- To maintain safe and healthy workplaces, plant and equipment’s methods of work.

- To provide detailed investigation into incidents or near-miss incidents and establish safeguards to prevent a recurrence.

- To provide for response to emergencies.

- To determine broad parameters of management at the site to achieve the goals and targets of safety.

- To establish and define the line of command for resolution of all-hazard prevention issues.

- Assigning individual responsibilities/accountabilities, hazard prevention and safety responsibilities at each level of the Plant team.

- Identifying hazardous operations within the scope of work and specially integrated preventive measures to mitigate the same.

TARGETS AND GOALS

- Zero lost time accidents

- Zero recordable injuries

- Zero health related issues

- Zero detrimental environmental incidents

- Full compliance with the Plant rules and safe systems of work

PURPOSE

The main purpose of the Plan is to ensure regulatory compliance and international best practice, manage Health, Safety, and Environmental issues, protect lives and prevent incidents in all phases of the Plant, where the hallmark of operations are efficiency and cost-effectiveness.

SCOPE

This OHSMP outlines the Plant and project requirements for DCGN/Contractors and lower-tier subcontractors at the site for the execution of work.

At a minimum, this Plan adheres to the applicable requirements of the Republic of Guinea, the Internal Finance Corporation Performance Standards and DCGN’s Environmental and Social Impact Assessment (ESIA).

FACTORY ENTRY AND EXIT INSTRUCTIONS

- After obtaining the entry permit, you will be informed of some familiarization procedures with health, safety and environmental precautions to be followed upon entering the factory.

- You will be provided with personal protective equipment according to the place to be visited inside the factory. You will be provided with personal protective equipment to distinguish you from the rest of the workers.

- An employee from the company will accompany you as soon as you enter the factory.

- Not to enter any of the raw handling areas unless you have permission to do so and after the approval of the EHS Manager or the person accompanying you.

- If the visit is by a group of visitors, the responsibility for strict adherence to safety procedures will be on the leader of the group and the company is not responsible for any irresponsible activity of the visitor.

- Let the visitor card that is provided to you be visible.

- The regulations and laws established by the company in order to preserve safety

- After completing the work for which you applied, you must return the entry permit signed by your host.

IN CASE OF EMERGENCY

In the event of an emergency, you must move to the nearest assembly point, and if you have any doubts in this regard, you should review the facilities and follow his instructions.

Visitors should park their cars aside so as not to cause any obstruction to traffic.

RESTRICTED AREAS

Production units, central control room, and automated laboratory are restricted areas.

SMOKING

Smoking is strictly prohibited within the factory boundaries.

PERSONAL PROTECTIVE EQUIPMENT

Safety helmets, safety shoes, goggles, respirators, and gloves must be worn at all times when visiting the rough handling areas. There are additional safety precautions that must be followed while working in elevated locations and isolated areas.

TRAFFIC LAWS

- The maximum speed inside the factory is 30 km/h for cars and pickups, and 20 km/h for heavy vehicles.

- Observe traffic laws and signs.

- Fasten seat belts.

- Parking cars in the parking lots designated for visitors.

- Ensure that the car parking space does not obstruct the emergency exits and the lanes of firefighting equipment.

- Not to exceed the prohibited areas by car, as this is strictly prohibited.

THE PRESERVATION OF THE ENVIRONMENT

- Just as we find that health and safety are at the heart of any activity and that their responsibility rests with everyone, so is the case with the environment.

- Please keep all areas tidy and clean.

- Waste is disposed of in the trash receptacles that are provided.

SECURITY REQUIREMENTS

- Not leaving any personal/valuable property unattended.

- Not to enter offices unless authorized in advance.

Group Companies

0.5 million tons per annum cement

Unit-1 1200 TPD, 0.5 million tons per annum cement commissioned, 2015.

18 countries

Group Presence is in 18 countries

5,000 people

Group provides direct employment to 5,000 people and indirect employment to 10,000 people of Africa

350 +

Along with more than 350 professionally qualified and experienced expatriates staff in Africa.